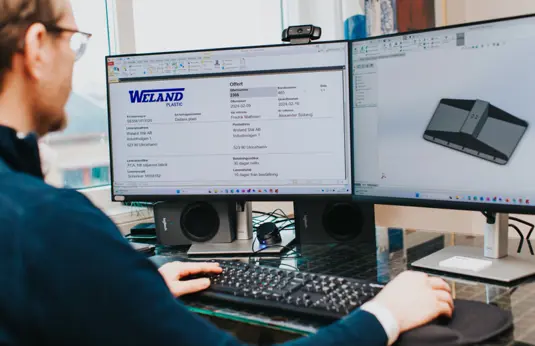

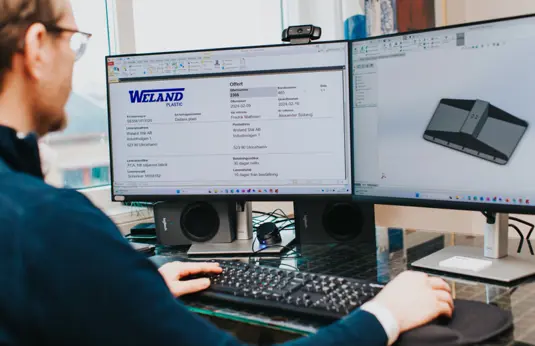

Product development

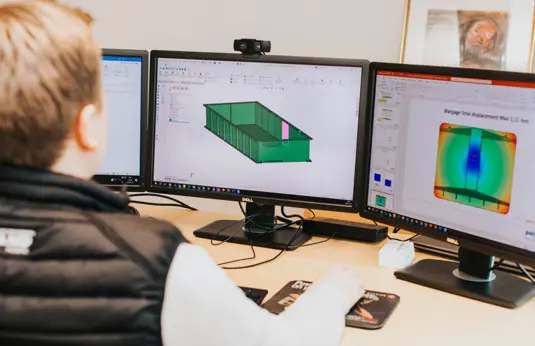

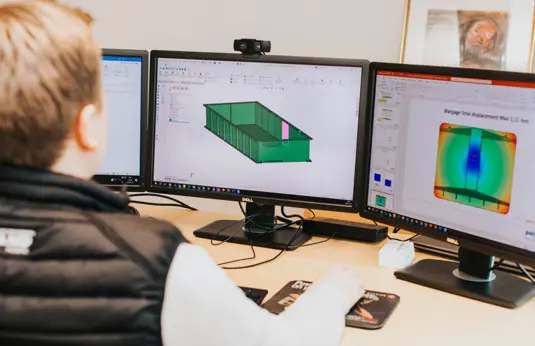

Weland Plastic's experienced technical project managers are involved throughout the entire development process - from the concept phase to final production. In order to ensure that each product satisfies the expected requirements in respect of functionality, performance, and safety, we can, via our pool of partners, produce prototypes to test and evaluate the product before it is put into production. We can also produce proposals for improvements and optimisations that can maximise the potential of the product. This gives you, the customer, a sense of assurance and makes Weland Plastic the clear and obvious choice when choosing a supplier.

Why plastic?

At present, plastic is used in almost every industry and, in certain areas, plastic is the only material that allow things to work. It is a multi-faceted material that can be easily shaped and adapted, its lightness making it ideal for use in products where weight is an important factor. In addition, it is also a material that can withstand significant stress. Every day, we use products that could not have worked if plastics had not been invented.

Project management

By combining our expertise within plastics manufacturing with our technical expertise, we can support you at every step of your project. We always work closely with customers, providing guidance in respect of design, choice of materials, and any modifications to the initial concept so that it meets expectations and is optimised in order to achieve a high level of quality and production technical economy. We always strive to maximise efficiency and quality in the manufacturing process, all while keeping costs down. This results in competitive and sustainable end products that last for a long time. All of which is good for you, your business, and the environment.

Inquiry/Quote

When you submit and inquiry to us, you can always expect a quick response, either in the form of a quote or a series of questions that we need answers to before we can take things further. In order for the process to be as efficient as possible, we will, in some cases, get back to you with a product critique on the basis of the documentation you have sent to us. This critique may centre on material choices, characteristics, or some other aspect that we believe can be improved in order to keep production costs down. We now also offer a design review, where the design and structure of the product is examined and evaluated to ensure that levels of quality and functionality keep to the initial requirements and expectations set out for the product. Our project managers keep in constant contact with our toolers and materials suppliers to iron out any questions.

When the order is placed

Once the order has been received, we document the scope, schedule, cost framework, and resource allocation for the project internally and/or with our partners. In this part of the process, we conduct a series of risk analyses (FMEA) and create a flow chart to ensure that each part of the project is carried out in a structured and efficient manner.During the design review, the design and structure of the product is examined and evaluated to ensure that levels of quality and functionality keep to the initial requirements and expectations set out for the product. Any procurement required for the project is planned into the schedule at the same time. If necessary, our project managers may conduct a design review with our toolers and materials suppliers to iron out any questions.

Safe work processes

We know how important it is that what we manufacture is compliant with the specifications and quality requirements you have set. As a partner and supplier to the automotive industry of many years, our work processes adhere to a very high standard. The automotive industry has some of the most stringent demands in respect of the strict quality controls it expects to be undertaken on what is manufactured. We have made the high standards of the automotive industry ours, so that all customers, regardless of the industry they operate in, can expect the same, proven working methodology that our automotive customers have demanded.

How can we help you? We are on hand to support you, answer your questions, and to tell you more about what our services can do for you and your business. The easiest way to get in touch is by phone or e-mail. We look forward to hearing from you soon!

Contact us